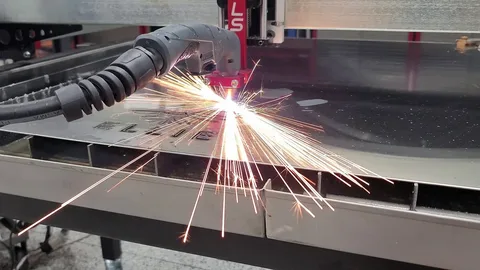

Cutting metal with a plasma cutter seems straightforward until molten metal begins collecting along the edge. That buildup—known as dross—can slow production, increase cleanup time, and affect part quality. Understanding why it forms helps operators fine-tune the process, especially in CNC environments where repeatability matters.

Excessive Cutting Speed Leaving Unmolten Metal Behind

Running the torch too fast is one of the most common contributors to dross. As speed increases, the plasma arc has less time to fully melt the metal beneath it. The molten pool becomes unstable, leaving behind partially fused material that hardens along the bottom edge. Slowing the cut allows the arc to penetrate cleanly through the plate.CNC plasma cutter operators often adjust speed based on material thickness, arc power, and part geometry. A CNC machine company typically recommends speed charts, but real-world fine-tuning still makes the biggest difference.

Low Amperage Failing to Fully Penetrate the Plate

Low amperage weakens the arc’s ability to push through the metal. Without enough energy, the arc only melts the upper layers, causing slag to cling to the underside. This is especially noticeable on thicker plate where heat must travel deeper. Increasing amperage strengthens the arc column, improves penetration, and reduces excess buildup. A plasma cutter performs best when amperage settings match the metal’s thickness and the cut speed being used. CNC plasma cutting machine operators often raise current levels during long contour cuts to maintain consistency.

Poor Gas Flow Disrupting the Plasma Arc Stability

Gas flow directly affects arc shape, temperature, and cutting force. If flow is too low, the arc weakens and loses directional focus, creating uneven cuts and heavy dross deposits. Excessive flow can cause turbulence that disrupts the molten pool. Proper gas pressure keeps the arc stable and helps blow molten metal away from the cut. Operators who work with CNC companies near me often receive guidance on selecting ideal gas flow settings for different materials and nozzle types. Consistent flow is vital for high-quality production runs.

Torch Height Set Too High Above the Material Surface

Correct torch-to-work distance plays a major role in cut quality. A torch set too high reduces energy concentration at the cut line. The arc spreads out instead of penetrating sharply, leaving behind rough edges and clumped dross.

Lowering the torch height tightens the arc and improves heat transfer. CNC plasma cutting machines use automated height control to maintain the correct distance as material warps or shifts. Maintaining this gap ensures the arc stays stable from start to finish.

Dirty or Worn Consumables Affecting Arc Focus

Consumables such as nozzles and electrodes naturally degrade during cutting. Worn components distort the arc’s shape, reducing precision and lowering the temperature at the cut zone. Dirty consumables also restrict gas flow, worsening the effect.

Replacing worn parts restores arc stability and prevents inconsistent dross patterns. Shops operating a plasma cutter learn quickly that consumable management is essential to quality control. A CNC machine company usually recommends maintenance intervals based on amperage and cutting hours.

Incorrect Gas Mixture for the Specific Metal Type

Different metals require different gases to achieve clean cuts. Mild steel often performs best with oxygen blends, while stainless and aluminum usually need nitrogen or other inert gases. Using the wrong mixture changes arc behavior and increases dross formation.

Metal-specific gas blends improve heat transfer efficiency. CNC plasma cutter operators who switch materials frequently rely on preset programs that match gas settings to metal type. Optimizing mixture choice tightens the arc and reduces cleanup time.

Inconsistent Travel Motion Causing Uneven Melts

Jerky movement or inconsistent travel speed disrupts the molten pool. Any hesitation allows metal to cool prematurely, causing rough spots along the edge. This is especially noticeable in curved or detailed cuts where steady motion is harder to maintain manually.

Automated CNC plasma cutting machines eliminate much of this inconsistency through controlled motion systems. However, poor programming, incorrect ramp speeds, or worn rails can still introduce irregularities. Smooth travel ensures the arc melts and ejects metal evenly.

Metal Impurities That Interfere with Clean Cutting

Not all metal has a uniform composition. Rust, paint, mill scale, or embedded contaminants can disrupt heat transfer. These impurities create hot and cold spots, leading to uneven melting and dross sticking to the bottom of the cut.

Cleaning the surface improves the arc’s ability to maintain consistent temperature. A plasma cutter performs noticeably better when cutting through clean metal. In high-precision environments, CNC companies near me often advise pre-cut surface prep for best results.

Back-dragging the Torch Without Proper Lead-out Control

Back-dragging occurs when the torch exits the cut in reverse direction or slows too much at the finish point. This leaves a buildup of molten metal at the end of the cut path. Poor lead-out control can also cause the arc to linger where heat concentrations are already high.

Adjusting lead-out programming helps create cleaner finishes. A CNC plasma cutting machine typically allows operators to set exit angles, slow-downs, and path extensions that reduce dross accumulation. Fine-tuning these parameters leads to smoother edges and better overall quality.

Dross formation reflects how well arc power, motion, gas flow, and material conditions work together. Amtec Solutions Group provides cutting systems, automation tools, and engineering expertise that help manufacturers achieve cleaner edges, reduce rework time, and optimize plasma cutting efficiency across a wide range of metals and production environments.